Under the Hood of Flight: A Guide to Aircraft Engine Parts

Aircraft engines are marvels of engineering, combining precision, power, and reliability to keep planes soaring safely through the skies. For aviation enthusiasts, mechanics, or anyone curious about what makes flight possible, understanding the parts of an aircraft engine is essential. In this guide, we’ll break down the key components, their functions, and why proper maintenance is critical.

1. The Engine Block

At the heart of an aircraft engine is the engine block, which houses cylinders and forms the framework for other components. Typically made from durable metals, the engine block must withstand extreme temperatures and pressures. Some modern solutions even use cast aluminum solutions for their lightweight strength and heat-dissipation properties. The block ensures stability and aligns all moving parts for optimal operation.

2. Cylinders and Pistons

Inside the engine block, cylinders are where combustion occurs. Pistons move up and down within these cylinders, converting fuel into mechanical energy. Each piston is connected to a crankshaft, transforming the reciprocating motion into rotational power that ultimately turns the propeller or turbine. The precision of these parts is vital; even a minor imbalance can reduce efficiency or cause engine wear.

3. Crankshaft

The crankshaft is the engine’s central rotating shaft. It receives the up-and-down motion of the pistons and converts it into rotational energy to drive the aircraft’s propeller or generate thrust in jet engines. Crankshafts must be incredibly strong to handle the stress of high-speed rotations while maintaining perfect alignment with pistons and connecting rods.

4. Valves and Camshaft

Airflow is controlled by intake and exhaust valves, which open and close in precise timing to allow fuel-air mixture in and exhaust gases out. The camshaft manages this timing, ensuring that the valves operate at the right moment. A properly functioning valve and camshaft system ensures efficient combustion, reduced emissions, and peak engine performance.

5. Turbochargers and Superchargers

Some aircraft engines include turbochargers or superchargers to increase air pressure entering the cylinders. This allows more fuel to burn efficiently, boosting power output. These components are especially common in high-performance aircraft, where maintaining power at high altitudes is essential. Regular inspections prevent wear that could lead to catastrophic failure mid-flight.

6. Fuel System Components

The fuel system includes pumps, injectors, and lines that deliver precise amounts of fuel to the engine. Modern engines rely on fuel injectors to atomize fuel for consistent combustion. Proper fuel system maintenance is critical, as blockages or leaks can affect engine performance and fuel efficiency.

7. Ignition System

The ignition system sparks the fuel-air mixture inside the cylinders, initiating combustion. Magnetos, spark plugs, and wiring work together to ensure each cylinder fires at the right moment. A misfiring engine can lead to reduced power, increased fuel consumption, or even engine damage.

8. Cooling and Lubrication Systems

Aircraft engines generate tremendous heat, requiring cooling and lubrication systems. Oil circulates to reduce friction between moving parts, while air or liquid cooling prevents overheating. Maintaining proper oil levels and checking for leaks is essential to prevent engine failure.

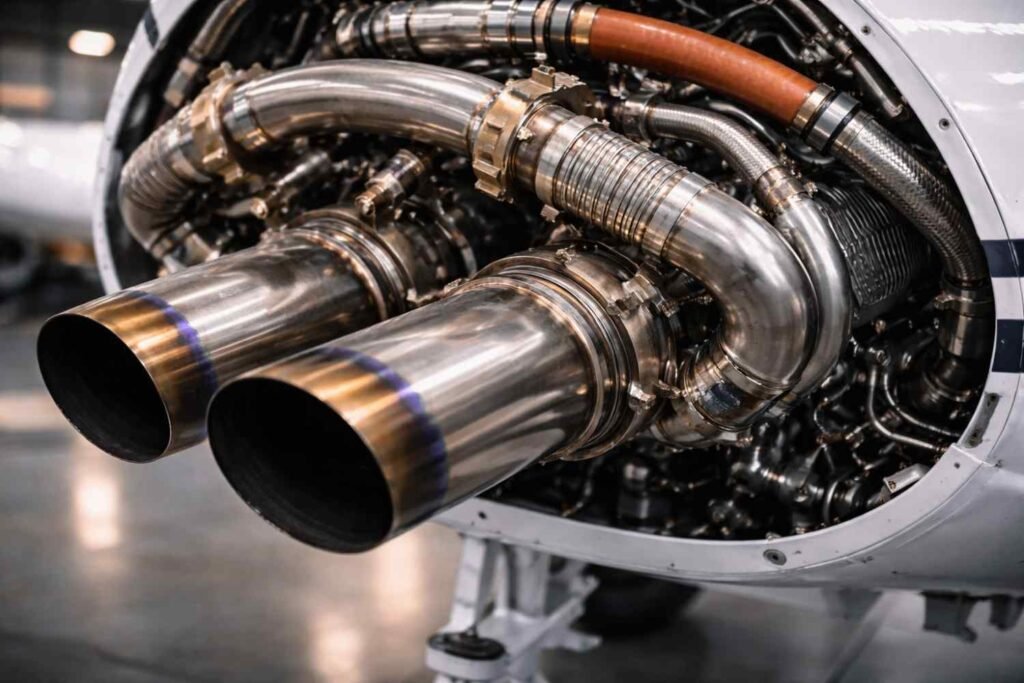

9. Exhaust System

Finally, the exhaust system removes combustion byproducts from the engine. Efficient exhaust systems reduce back pressure, improve engine performance, and minimize harmful emissions. Many performance upgrades and repairs focus on exhaust system efficiency.

10. Maintaining Engine Performance

Proper maintenance is key to keeping all these components working harmoniously. Regular inspections, timely replacements, and adherence to manufacturer specifications ensure engines remain reliable and safe. Even small issues, like a worn valve or faulty piston, can compromise efficiency or cause dangerous malfunctions. For aviation professionals, knowing the parts under the hood is not just educational—it’s crucial for safety.

In Conclusion

Understanding aircraft engine parts—from the engine block to the exhaust system—provides insight into the remarkable engineering that powers flight. Each component, whether it’s a piston, crankshaft, or camshaft, plays a critical role in transforming fuel into motion.

With proper care, maintenance, and innovations like cast aluminum solutions, aircraft engines continue to deliver the reliability and performance pilots rely on for every journey. Whether you’re an aspiring mechanic, aviation student, or curious traveler, getting under the hood offers a fascinating glimpse into the machinery that keeps us flying safely above the clouds.